What is SIRD

SIRD is Scanning Infra-Red Depolarization. SIRD measures stress in optically transparent materials utilizing a non-contact and non-destructive technology for:

--Si wafers up to 300mm

--Compound materials

--Solar cells

Why SIRD needed

Reason is Stress will be caused by any abrasive manufacturing or temperature-related process step during the manufacture of wafers as well as in IC fabs. Small defects cause a much larger Stress area. Even defects near the edge propagate deep into the wafer Analytical operations reveal the actual defect together with its true location.

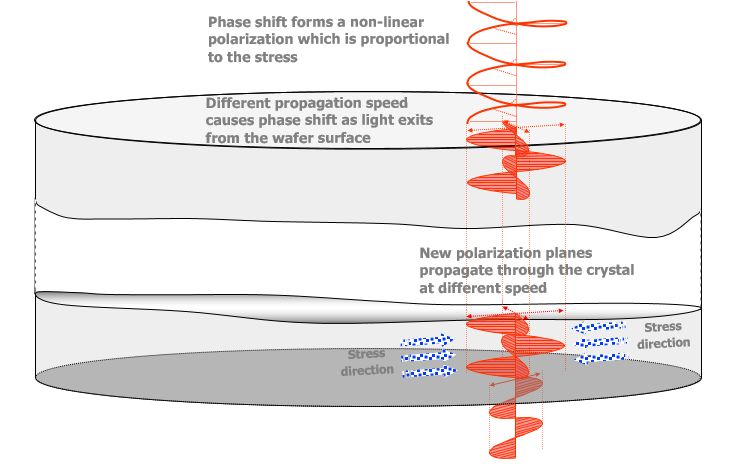

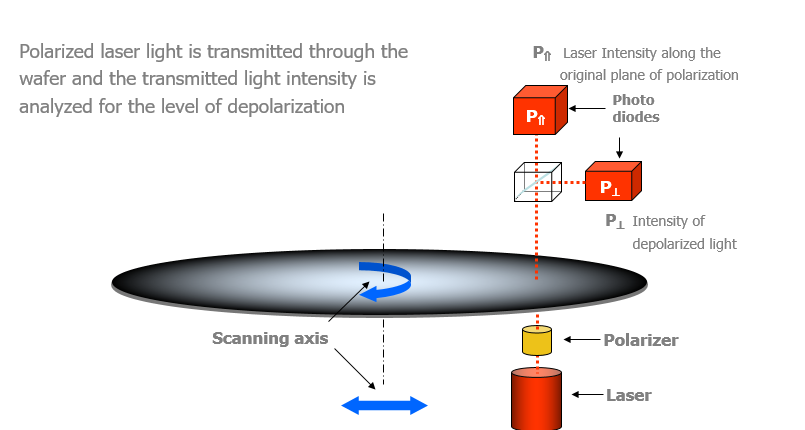

How SIRD execute stress measurement

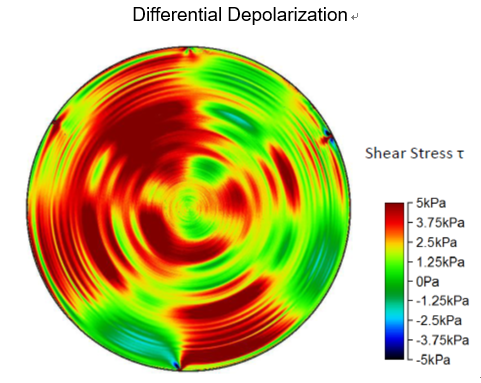

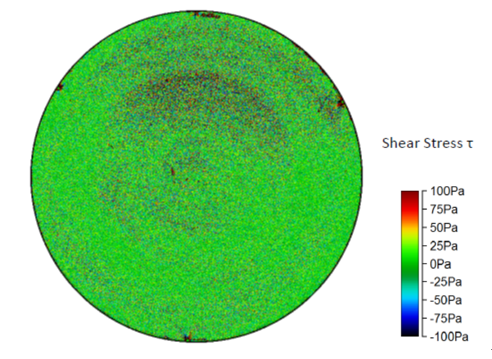

Bare wafer measurement sample

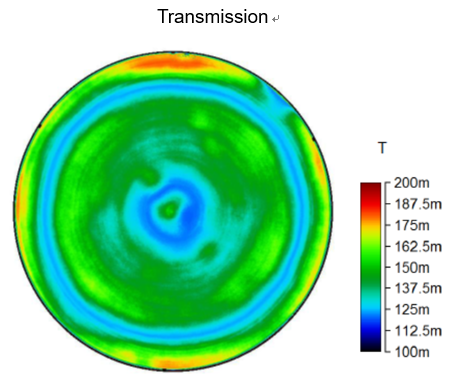

Global defects

Big ring like patterns probably caused by non-uniformities of dopant or impurity concentration

Local defects distribution:

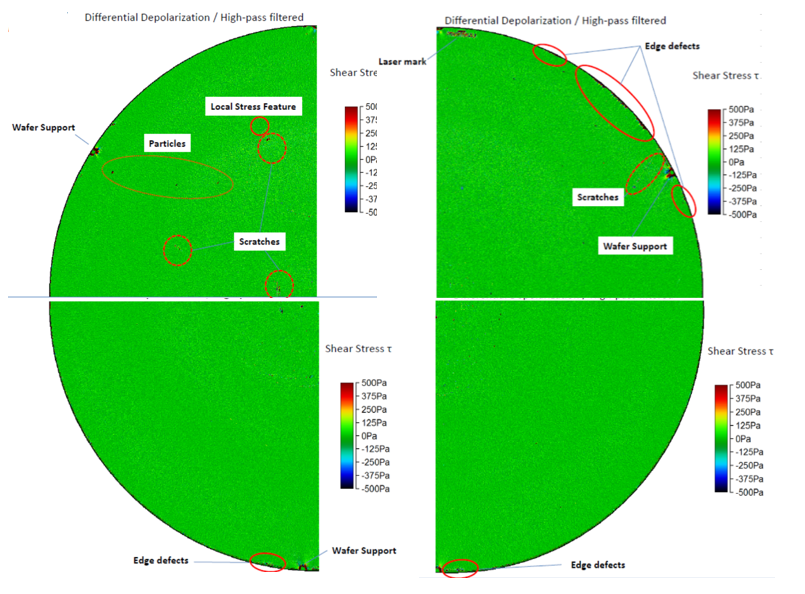

Differential Depolarization / High-pass filtered

Defects distribute in different place on wafer