PVA&Tepla VPD system and module

(Primitive name Munich Metrology)

Munich Metrology GmbH. A wholly owned subsidiary of PVA Tepla, has over 20 years of experience in VPD and Gas Phase Decomposition equipment. Munich Metrology was acquired by PVA Tepla in 2012. Munich Metrology products are manufactured by PVA Tepla, Extending the Metrology capabilities for semiconductor group.

Products Line

WSMS - Wafer Surface Measurement System

Munich Metrology offers the most advanced, fully integrated VPD measurement systems. The WSMS includes a cutting-edge VPD, Gas Phase Decomposition, the most advanced precise chemical delivery system that automatically provides all required analytical calibration of chemical VPD and all chemical sample collection system integrated ICP-MS. It is a computer controlled system that accepts remote commands and provides real-time measurement results through the factory automation interface in a complete measurement system by SECS/GEM. The advantages of the WSMS include:

Munich Metrology offers the most advanced, fully integrated VPD measurement systems. The WSMS includes a cutting-edge VPD, Gas Phase Decomposition, the most advanced precise chemical delivery system that automatically provides all required analytical calibration of chemical VPD and all chemical sample collection system integrated ICP-MS. It is a computer controlled system that accepts remote commands and provides real-time measurement results through the factory automation interface in a complete measurement system by SECS/GEM. The advantages of the WSMS include:

-

Full Automatic

-

Minimum dection limit

-

Faster measurement results

-

Real-time operational processes

-

Measurements with precise, error-free, dosing, dilution, mixing and delivery to both VPD and ICP-MS operations

-

No need for manual calibration and reduce costs

-

Utilities Dimension

-

Power : 220/110 V, 2.2 kW

-

DI water : 1.5 bar (20 psi), 2 l/h

-

Nitrogen : 1.5 bar (20 psi), 0.7 m³/h

-

Exhaust : 50 m³/h

-

Drain Depth : 1507 mm

-

Width : 2065 mm

-

Height : 2140 mm

-

Table Top : 945 mm

-

Weight : 1100 kg

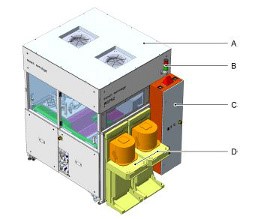

WSPS - Wafer surface preparation system (VPD Preparation)

The WSPS system integrated with processing modules, robot control, cassette stations, and FOUPS in the fixed load port, which provide filtered clean air, tools, and power to each module. WSPS software provides complete system operational capabilities and data collection, including custom recipe setup, job definition, job execution, wafer priority and remote monitoring and operation management.

The WSPS system integrated with processing modules, robot control, cassette stations, and FOUPS in the fixed load port, which provide filtered clean air, tools, and power to each module. WSPS software provides complete system operational capabilities and data collection, including custom recipe setup, job definition, job execution, wafer priority and remote monitoring and operation management.

-

scan the full wafer surface for residue

-

Module design

-

Automatic processing

-

Suitable for silicon wafers and other material surfaces

Programmable automatic decomposition fuming system

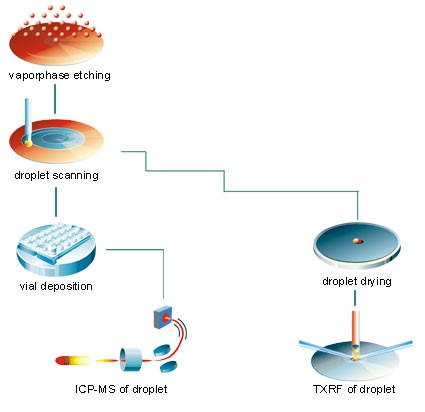

The PAD-Fume is a modular part of Munich Metrology ‘s Wafer Surface Preparation System (WSPS) for ultra-trace metal contamination analysis of silicon wafer surfaces and oxides.It can be used in combination with the automated droplet scanner PAD Scan and the PAD-Dry (for TXRF analysis only).

The PAD-Fume is a modular part of Munich Metrology ‘s Wafer Surface Preparation System (WSPS) for ultra-trace metal contamination analysis of silicon wafer surfaces and oxides.It can be used in combination with the automated droplet scanner PAD Scan and the PAD-Dry (for TXRF analysis only).

PAD-Scan, Sample Collection Module PAD-Scan

The PAD-Scan offers a new quality for highly sensitive VPD analysis of silicon wafers. Its fully automated operation eliminates all particle contamination caused by human operators and decreases blank values substantially resulting in superior detection limits.

The PAD-Scan offers a new quality for highly sensitive VPD analysis of silicon wafers. Its fully automated operation eliminates all particle contamination caused by human operators and decreases blank values substantially resulting in superior detection limits.

With it precisely controlled scanning procedure the PAD-Scan converts VPD into a reliable preparation method with good repeatability, ideally suited for quality control of wafer surfaces in front end processing.

Thanks to sophisticated partial scanning modes any area of the wafer can be selected for collecting the VPD residue. Robotic wafer handling capability is available for all wafer diameters up to 300 mm.

Programmable Automatic Droplet Dryer

The PAD-Dry prepares the droplet for TXRF analysis by drying on the wafer, It uses vacuum and moderate heat for a smooth and fast drying.

The PAD-Dry prepares the droplet for TXRF analysis by drying on the wafer, It uses vacuum and moderate heat for a smooth and fast drying.

Automation

AS a production oriented tool the WSPS offers all options for automatic wafer handling including SMIF and FOUP load ports. All software standards like SECS/GEM are implemented for integration into the fab control system.

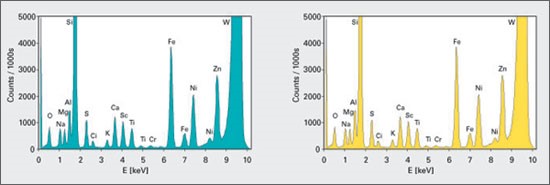

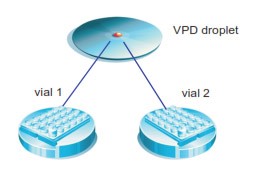

VPD principle

A calibrated droplet (50 to 350 μl) of a chemical solution or ultrapure water is pipetted onto the wafer and guided by a high purity tube over the wafer surface following a programmable pattern. After completion of the scan the tube is detached from the droplet with a short nitrogen pulse. The droplet can be allowed to dry at a predefined position on the scanned wafer (for TXRF analysis) or it can be transferred by the pipette to a micro vial (for ICP-MS analysis). Scanning tube and pipette can be cleaned with a cleaning solution and rinsed with ultrapure water before and after the scan.